Mr T. Fukishma of F-TeCon Pty Ltd carried out the

modeling (

Bennett &

Fukushima, 2003) to investigate the impact of PCI

coal quality on the operation of a blast furnace. The model was

used for a quantitative study on the influence of ash content of

the PCI coal on blast furnace operation, particularly focusing on

the impact on operating costs. For this study the blast

furnace process parameters shaft efficiency, reserve zone

temperature, heat losses of upper shaft and lower shaft and

theoretical flame temperature at raceway were constant for all

calculations. One coal was used in all calculations with different

amounts of ash – 8, 9, and 10 % ad. These calculations

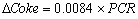

indicated that the change in coke requirements (kg/tHM) per 1

percent ash change in the PCI coal varies with injection rate

as:

For an injection rate of 150 kg/tHM, an increase

of 1% in the ash of the injected coal would result in a 1.2 kg/tHM

increase in the coke rate. In addition to this increase in

coke rate there is also a need to adjust BF operating parameters

(e.g. blast volumetric rate, temperature and oxygen, and slag

chemistry), which results in a net increase in BF energy

requirements and other raw materials. Therefore, the cost impact of

an increase in ash of the injected coal is dependent on the coke

costs and the cost of auxiliary fuel used within the plant.

The increase in coke rate per 1% increase in ash

determined by this study is significantly less than that suggested

by other authors. Poveromo [1] suggests that for furnaces with

total fuel rates of 500 kg/tHM every reduction of coke ash

(or injected coal ash ) of 1 % would reduce coke rate by 6

kg/tHM. Xi Ping and Suen [2] state that for each one percent

of ash will increase the blast furnace fuel rate by two

percents. Therefore, the ash content of the PCI coal must be

at least 1.5 percent lower than that of met coke.

Brouwer and Toxopeus [3] in summarising the PCI

operating results at Hoogovens IJmuiden blast furnace derived a

relationship between replacement ratio and the properties of the

coal injected (given in Appendix A). This relationship shows that

ash increases replacement ratio and therefore would lower coke

rate.

There is a value-in-use penalty for increased

ash, but for the majority of coals traded as PCI coals the ash

differences are small and the composition of the ash may be more of

a concern in the future.

[1] Poveromo, J., 2004, Blast furnace fuel

injection trends, Met Coke World Summit, Chicago, October

2004.

[2] Xi Ping, P., Suen H., 2003, PCI Application

in blast furnace operation and market trend in China,

McCloskey’s 8th Annual Australian Coal Forecast 2004

Conference, 24 – 25 November 2003.

[3] Brouwer, R.C., Toxopeus, H.L., 1991, Massive

coal injection at Hoogovens IJmuiden BFs, Revue de Metallurgie.

Cahiers d'Informations Techniques, V88, N4, Apr 1991