At high heating rates of PF flame or in a blast

furnace tuyere the volatile yield is greater than that measured by

a proximate analysis. The "Q factor" is that ratio of the

expected high temperature yield compared to the proximate volatile

matter. There is very little data published on the higher

temperature volatile yield of Australian coals, the data of Wall

and others (1992), shown in the figure below, does indicate high Q

factors for high rank coals. The data from Ashman and others

(1999) and Haywood and others (1995) show similar trends to the

data of Wall and others, though the Q factors calculated from this

data for low volatile coals were not as great. CoalTech has

compared over 11 different methods for determining high temperature

volatile yield.

Lately there has been considerable literature on

the use of phenomenological coal models to predict

devolatilisation, volatile nitrogen release and char

formations. Generalised devolatilisation models (network

models) are based on chemical/physical descriptions of the

structure and processes of the coal particle as the particle heats

up and pyrolyses. The three main coal devolatilisation models that

include nitrogen release are:

-

- FG-DVC

[1] functional group-depolymerization vaporization cross-

linking

-

FLASHCHAIN [2]

- CPD

[3,4,5] chemical percolation- devolatilisation

The reported predictions of these

devolatilisation models are shown below.

Solomon and Fletcher reviewed the predictive

ability of these network models. Brewster and others (1995)

found that FG- DVC gave improved predictions of mass loss compared

to the usual two step model for coal devolatilisation. FLASHCHAIN

is being incorporated into EPRI’s software package Coal

Quality Impact Model to improve the NOx

predictions.

The CPD model differs from other network models

in that only one empirical parameter is used to fit the

devolatilisation of all coals, all other coal-dependent structural

coefficients are taken directly from 13C NMR

measurements. Recently, Perry (1999) expanded CPD model to

include nitrogen release as tar and light gases (CPD- NLG).

To extend the use of CPD to when 13C NMR

measurements were not available Genetti (1999) produced equations

of best fit to allow coal proximate and ultimate analysis to be

used to determine the NMR based inputs to the model.

Some work has been carried out by CoalTech to

evaluate the CPD-NLG model, this has been limited to evaluating 8

coals using the NMR inputs calculated based on Genetti’s

work. Reasonable agreement was found with Entrained flow reactor

data, but for wire- mesh data (higher temperatures) the CPD-NLG

model predicts a smaller increase in volatile yield than the actual

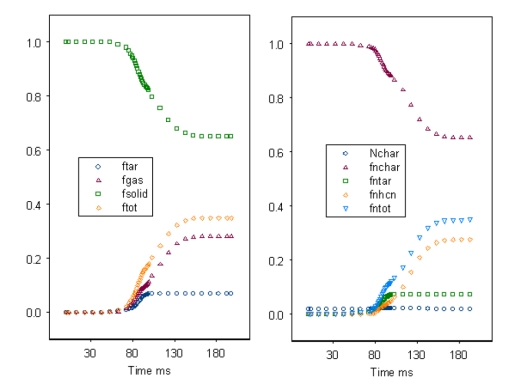

data. Typical yield curves for char (fchar), tar (ftar), light

gases (fgas) and total volatiles (ftot) with the fraction

conversion of nitrogen to the major species are given in Figure

below.

To ascertain the influence of peak temperature on

the CPD-NLG model predictions two final temperatures were used,

1500 C and 2000 C, with a heat up time of 300 ms. For a high

volatile coal, the volatile yield did not increase significantly (Q

factor of 1.01), the volatile nitrogen increased by about 5% and

the char nitrogen decreased by 5%. For a medium volatile coal (24 %

daf), the volatile yield only increased by 2% (Q factor of 1.45),

the volatile nitrogen increased also by 2% and the char nitrogen

decreased by 2%.

[1] Solomon P., et el 1993, Fuel 72:469.

[2] Niksa S., 1996, “Assess coal quality

impacts on your personal computer”, 1996 International AFRF

Symposium.

[3] Fletcher T., 1992, Energy & Fuels,

6:414.

[4] Fletcher T., 1999, “User’s manual

for the CPD Model”, Brigham Young University, , 1999.

[5] Fletcher T., Kerstein A.R., Pugmire R.J.,

Solum M., Grant D.M., 1999, “A chemical percolation model for

devolatilization : summary”, Brigham Young University, ,

1999.

[6] Jones J.M., Patterson P.M., Pourkashanian M.,

Williams A., Arenillas A., Rubiera F., Pis J.J., 1999b,

“Modelling NOx formation in coal particle combustion at high

temperature: an investigation of the devolatilisation kinetic

factors”, Fuel 78, 1999.

[7] Niksa S., Muzio L., Fang T., Hurt R., Sun J.,

Mehta A., Stalling J., 1999, “Assess coal quality impacts on

NOx and LOI with EPRI’s NOx-LOI predictor”, Coal

Quality Evaluation Tools, EPRI 1999.